Aluminum is an eco-friendly material that is widely used in windows and doors, CTALU is well-equipped to produce casement windows, sliding windows, Swing door and folding door frame, thermal insulated series and other aluminum window and door sections that meet ISO9001 and CQM standards.

We are available in 38 series, 50 series, 70 series, 798 and 898 series and so on. Thickness, strength and oxide film shall comply with the relevant national standards.

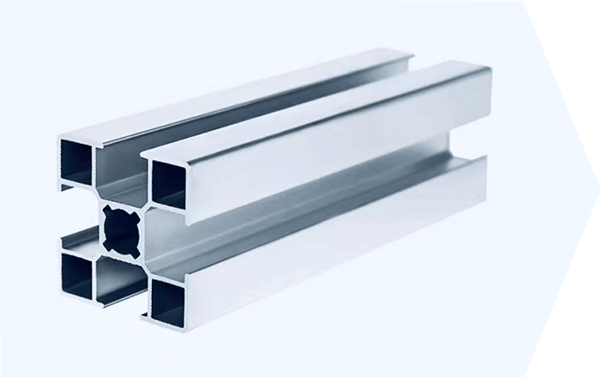

Industrial aluminum profiles can be widely used in electronics, medical, aviation, automotive and other industrial fields. industrial profiles produced by CTALU can achieve high corrosion resistance and excellent weldability with common surface treatments: powder coating, anodizing, electrophoresis, etc.

After the technological innovation all over the world, the market of industrial aluminum profiles is developing at a high speed, with a wide range of applications such as T-slot, Heat sink, etc. CTALU offers high precision profiles to our customers.

Standard aluminium refers to a number of conventional aluminium profiles, including Angle, Bar, Tube, H-Shape, louvre, etc. CTALU aluminium profiles can be used for billboards, mirror frames, flooring, etc.

All profiles can be customised and produced in open moulds. All the production strictly follows the Chinese aluminum manufacturer's standard of GB5237. The thickness and size of aluminum profiles are according to the customer's requirements, and we are committed to producing high gloss and high quality aluminum surface.

According to the aluminium profile in the customer's market, communicate with the customer about the size, thickness and other data, the engineer will design the corresponding CAD drawings.

For different surface treatments, size requirements, open a new mold, and start production after 7-10 days.

Based on the quantities of order, extrude the private moulds, ensure extrusion quantities ± 3% of the order, gloss, weight ,size inspection during production.

After extrusion, according to the order, the hardened aluminium profile turn to anodized (up to AA10 level), or powder coated (up to corrosion resistance and resistance tests).

QC will check the hardness, color, thickness, size, film, packaging of aluminium profiles, etc.,

Mass production finished, confirm the shipping date with the customer in advance; customs clearance information; factory inspection preparation; confirm the quantity and quality of the aluminium sections. At last, loading and shipping the container.

Ele-porcelain aluminum profile is a new type of aluminum alloy surface treatment process, the treatment of electrophoresis for matting, combined with the special climate of China to improve the chemical products needed for oxidation.

As porcelain swimming has very strict requirements on oxidation technology and production equipment, Cheetah uses pure imported coloring power supply to produce aluminum profiles with very fine surface.

EP is the abbreviation of electrophoretic phenomenon, which refers to the phenomenon of charged particles moving toward the electrode opposite to their electrical properties under the action of an electric field.

The technique of using charged particles moving at different speeds in an electric field to achieve separation is called electrophoresis.

Vacuum wood grain lamination technology: After the metal products are electrostatically sprayed well, the wood grain is transferred to the surface of the aluminum profile through the method of thermal transfer.

The wood grain transfer technology of CTALU is suitable for: aluminum alloy doors and windows, security doors, fire doors, steel and wood furniture, file cabinets, computer housings, household appliances, metal trims and other high temperature resistant metal materials.

Powder coating refers to: using powder spraying equipment (electrostatic spraying machine) to spray powder coating onto the surface of aluminum profiles. Under the action of electrostatic, the powder will be evenly adsorbed on the surface of the aluminum profile, forming a powder coating; the powder coating is baked at high temperature to form the final coating.

The coating effect of powder coating is better than the spray painting process in terms of mechanical strength, adhesion, corrosion resistance and aging resistance, and the cost is lower than the spray painting technology

Anodic oxidation, the electrochemical oxidation of a metal or alloy. The process of forming a layer of oxide film on aluminum products (anodes) under the action of an applied electric current in the corresponding electrolyte and under specific process conditions for aluminum and its alloys.

Cheetah developed and manufacture the aluminium extrusion profiles for more than 10 years, as a leading company of aluminium profiles, Cheetah is commited to improve the glossiness, corrosion resistance and the weather resistance of the surface of aluminium profiles.

Our factory is well equipped with melting and casting furnance, extrusion lines, anodizing and powder coating production line. with a total annual output of 40,000 tons, CTALU produces a broad field of aluminium extruded products, including door and window frame, industrial profiles, solar panel framing, louver system, standard sections, aluminium tubes, angles and u-channels. We have more than 60 engineers to help you start the customized service.

These are things that our customers demand not only of products they buy from us, but also from us.

Meeting their expectations is our daily challenge.Every item we offer has to meet the following criteria:

We can do anodizing(bronze, silver, gold and black color as you required); electrophoresis; powder coating and wood grain; sand blasting and mill finish is also available.

Packaging collocation as cutomers' requiments

7-10 days to build a new moulds, mass production takes 15-20 days for a 40HQ.

Telegraphic transfer(T/T) deposit and balance payment against B/L copy; Letter of credit(L/C) is also available.

2 metric tons per color; Free samples can be offered

5.8-6.4 meters are the standard profiles, the specific length could be cutomized.