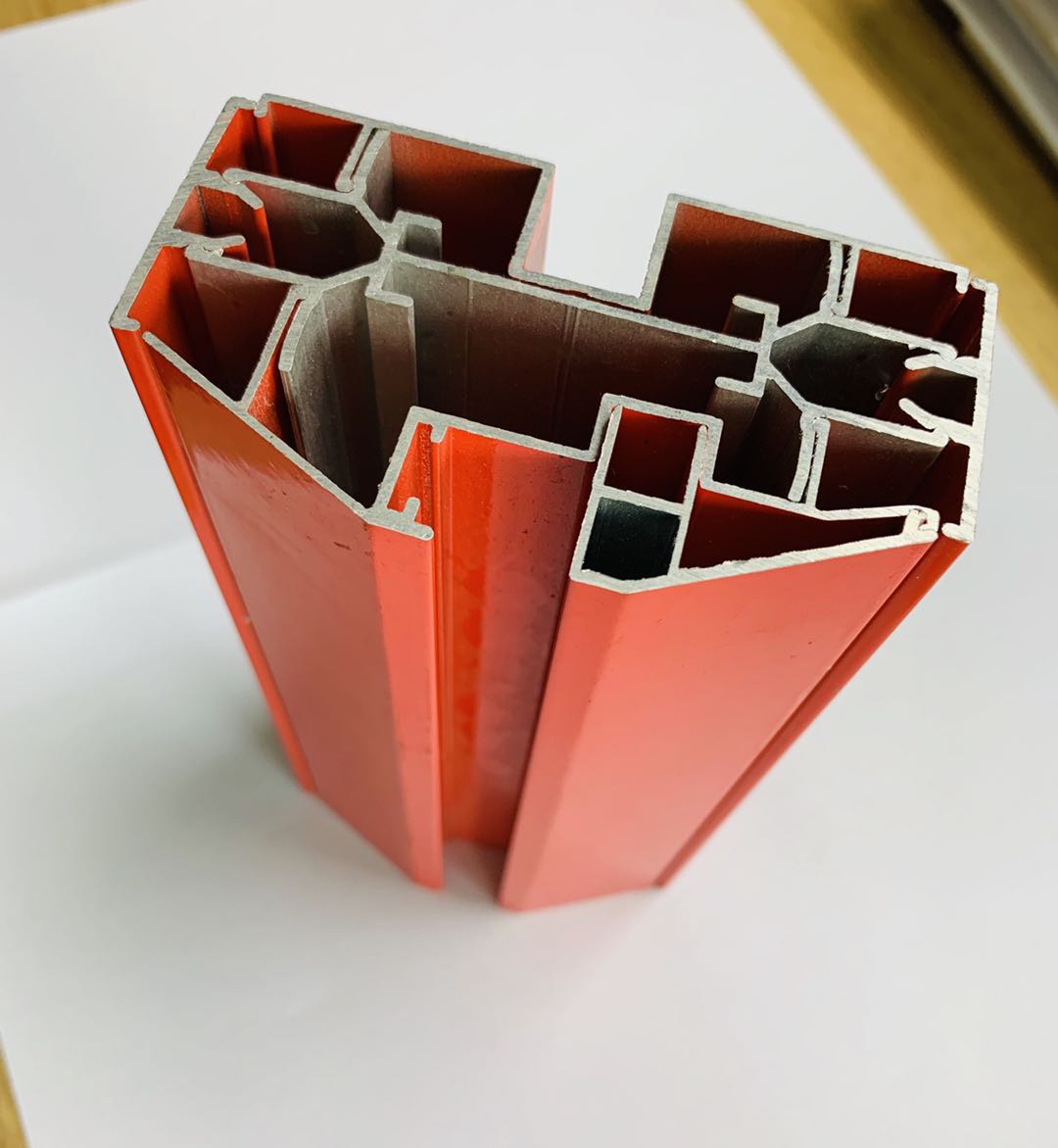

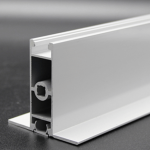

Cheetah Aluminum manufactures and exports high-quality aluminum tubes. Depending on the needs of each country, our factory produces a variety of sizes of aluminum tubing, such as aluminum square tubing, aluminum rectangular tubing, and aluminum round tubing. To meet market demands, we offer OEM service for aluminum extrusion tubing profiles, as well as customized extrusion thickness and diameter. To obtain high-performance aluminum profiles, high-quality raw aluminum ingot must be used during the manufacturing process.

Advantages of Aluminum Tubing

When it comes to aluminum square tubing, those in the construction industry are aware that its market recognition has grown dramatically in recent years. Aluminum square tube development has been rapid in recent years, and it has been praised by construction industry experts. For all types of engineering construction, aluminum square tube is preferred as a ceiling decoration material. The market for tubular aluminum is constantly expanding, whether it is used in government projects, public places, or home decoration.

So, what are the benefits of aluminum tubing (or aluminum pipe) that can entice buyers in a competitive market?

First, the aluminum square tube is available in a variety of specifications and can be customized to a length within 6.4 meters. The bottom has a minimum width of 20mm and a maximum height of 400mm. With so many options, any designer’s design will be satisfied.

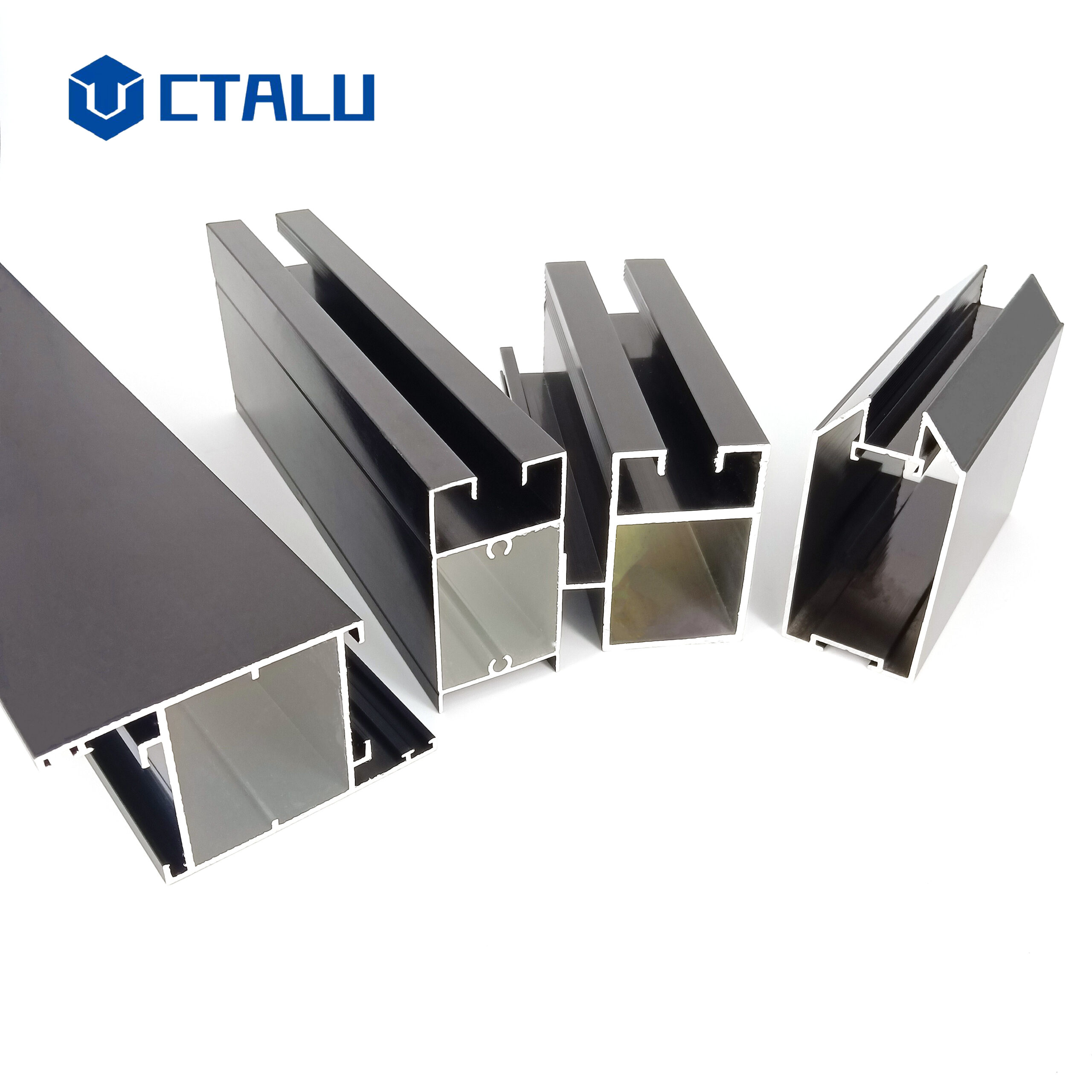

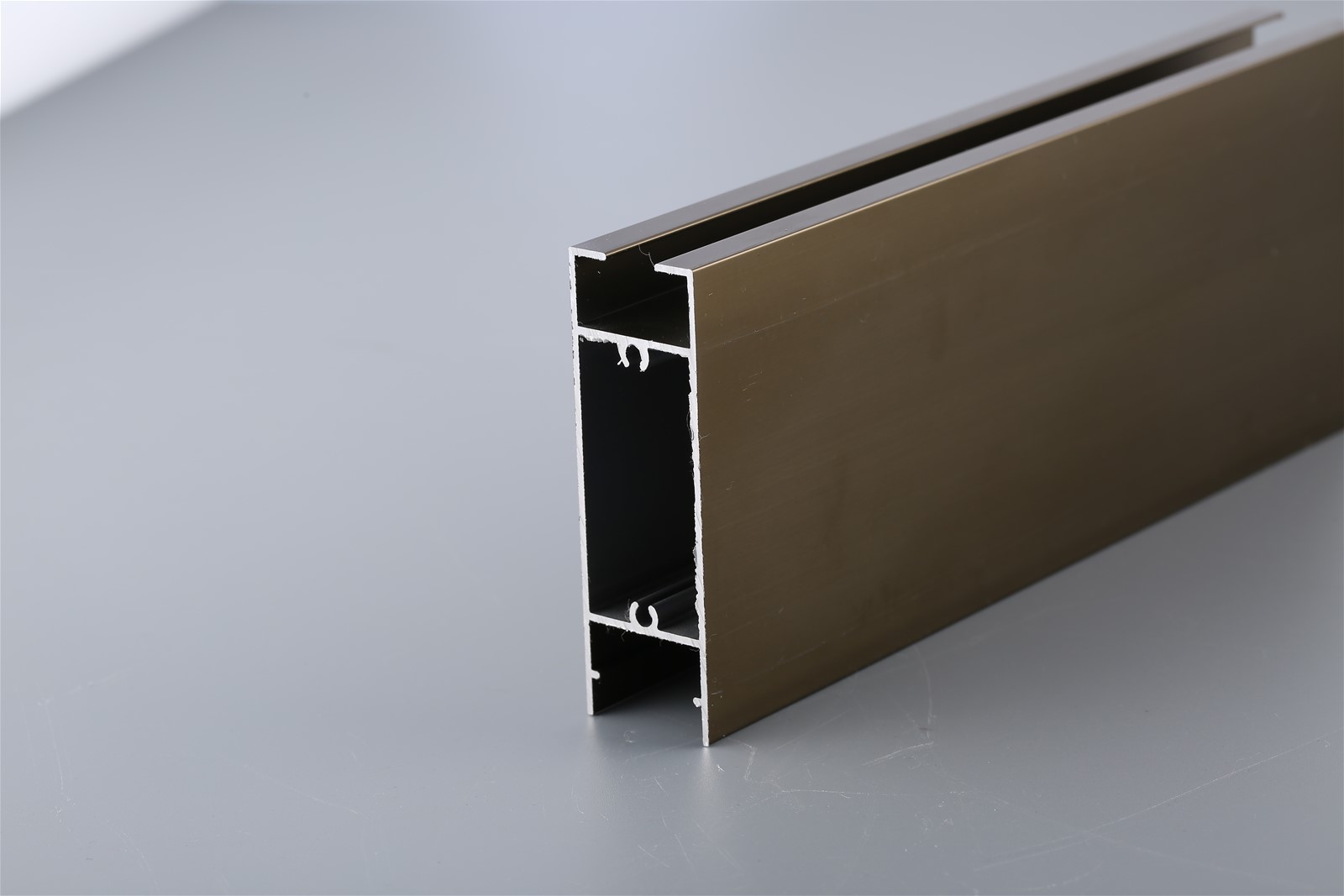

Second, the aluminum square tube can have various surface treatments. Cheetah Aluminum can select the most cost-effective surface finishing method based on the needs of the customer. Heat transfer wood grain, like powder spraying, is one of the most popular aluminum square tube processing methods. PVDF and other processes, on the other hand, are less common and must generally be used in areas with high corrosion resistance or high weather resistance.

Furthermore, there are numerous aluminum square tube shapes available. Aside from the standard straight aluminum square tube, there is also curved arc aluminum square tube, wavy aluminum square tube, and other distinctive aluminum square tube products. Cheetah Aluminum tailors aluminum profiles and molds to customers’ specifications, from drawings to samples. We must meet the needs of our customers as a professional aluminum tubing manufacturer.

Different Application of Aluminum Tubing

Aluminum square tubes are widely used in construction and home decoration. In general, aluminum square tubing can be used for the indoor ceiling. Connect using some accessories. Simultaneously, aluminum is used in some dust-free workshops. Because of the numerous benefits of aluminum profiles, the use of aluminum profile square tubes and associated accessories to make the working environment more environmentally friendly and clean.

The aluminum profile square tube from Cheetah Aluminum can also be used for interior partition walls, and the use of wood grain color aluminum surface enhances the overall effect.

Other building materials rust over time, such as iron or galvanized steel. Once the decorative materials rust, they will harm human health and the living environment.

Aluminum square tube is also commonly used in aluminum doors and windows. Windows and doors that are screwed or riveted together are typically supported by aluminum square tubes on either side of the door or window. When we are using the anodized aluminum square tube, the service life is greatly increased. Aluminum doors and windows will not fade when exposed to sunlight.

Cheetah Aluminum is a supplier of aluminum extrusions for windows and doors, automobiles, and boats. With our ability to manufacture virtually any extrusion to your specifications. Within your budget and with a timely lead time.

Service in Cheetah Aluminum

Surface finishing options include mill finishing, powder coating (custom color), anodizing, and others. It is available in a variety of colors. For over ten years, our aluminum profiles have high corrosion-resistant. The mature process enables us to meet the China Aluminum Association’s inspection standards.

Cutting to size: We provide cut-to-size service. With over ten years of production experience, we have very strict quality control. Aluminum profiles are typically exported in lengths of 5.8 m, 5.95 m, 6 m, and 6.4 m. We carefully control the length tolerance range. Each aluminum profile goes through at least three processes before being delivered to the packaging department.

Weight Control: As we all know, market competition is fierce in every country. As a result, we can assist our customers in controlling the weight and thickness of aluminum profiles in order to increase their profitability. Different thicknesses ranging from 0.65mm to 1.0mm are used in various areas. Cheetah Aluminum assists customers in calculating the cost of aluminum extrusion at various thicknesses while maintaining the performance of the extruded profiles.

Cheetah Aluminum has a complete aluminium profile production line, from mill finishing, to any kind of surface treatments, such as anodizing profiles or powder coating profiles, wood grain or electrophoresis.

Any questions please send to us, please feel free to contact:

Wechat / Whatsapp: +86 16603008969

Email: simon@ctalu.com