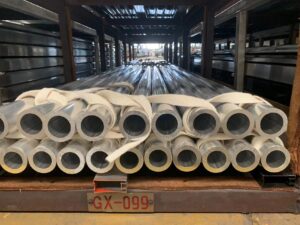

When it comes to aluminum profile purchasing, the major producer in the whole world is a topic inevitable. Make a comprehensive survey of the distribution of mineral resources, bauxite is mainly found in Guinea (7.4 billion MT), Australia (6.5 billion MT), and Brazil (2.6 billion MT).

According to 2015 data from the U.S. Geological Survey: As of 2014, the total global aluminum production capacity was 63.7 million tons, China accounts for about 51 percent of aluminum capacity.

But what is the reason that China has such a high capacity for aluminum? In the following article, we are going to set forth the factors and comparisons.

The supply of raw aluminum

Under the background of global carbon neutrality, electrolytic aluminum production in Europe, America and Oceania will basically maintain the current amount, and it tends to go down. Africa and South America have limited growth due to some factors such as infrastructure. Asia’s growth is mainly in the Middle East, where cheap energy is the main driver, but the overall space is limited. According to the data of the International Aluminum Association, the global output of electrolytic aluminum in 2020 was 65.267 million tons, up 2.46 percent year-on-year.

In terms of production areas, China is the biggest producer of electrolytic aluminum, accounting for more than half of the global output in 2020, accounting for 57.18%.

Availability of other metals

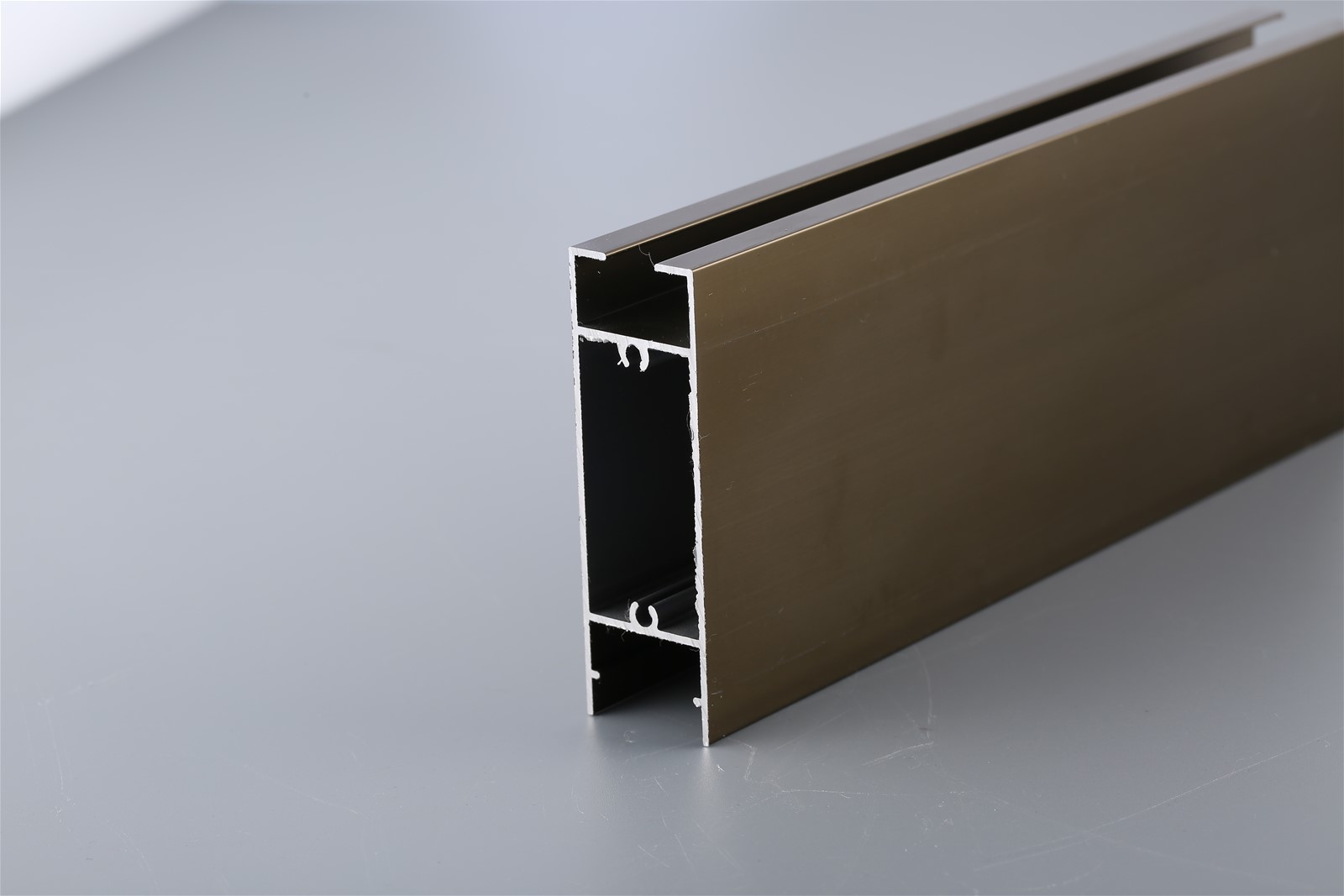

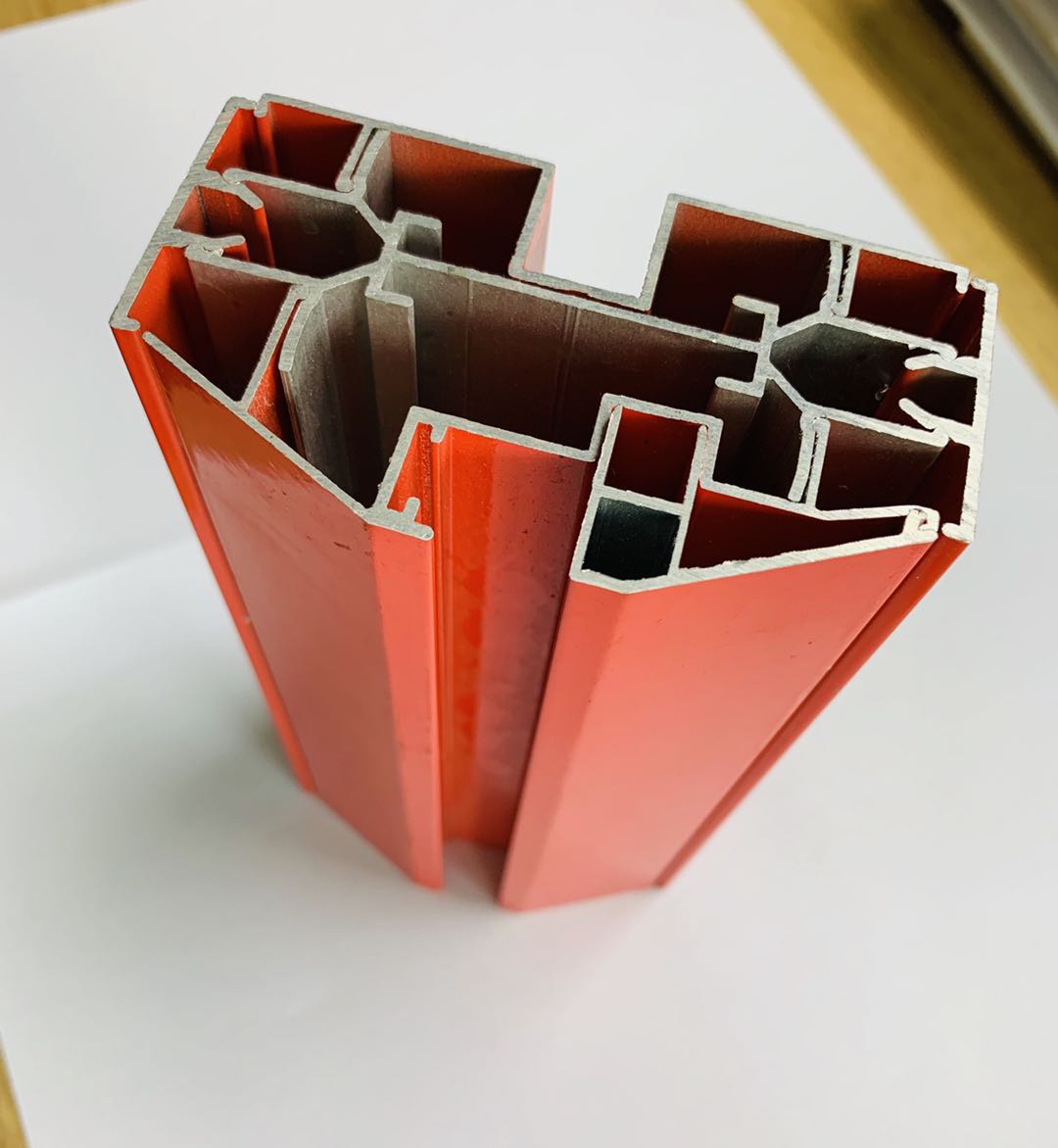

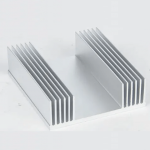

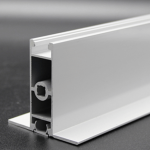

Regarding to the formation of aluminum, we have to talk about its components. Aluminum alloy is one of the light metal materials, which is an alloy based on aluminum with some other alloying elements. For example, the aluminum architectural profiles, especially the window and door systems, like frame, fan, center pillar, interlocker or lock stile, usually we will use 6063 series aluminum alloy for extrusion. Because of the advantages of 6063 alloy below:

- Wind pressure resistance

- Assembly performance

- Corrosion resistance

- Excellent welding performance

6063 aluminum alloy is mainly composed of aluminum, magnesium and silicon. China has set up wholesale markets for metals in various cities since 2000, it’s easier for each aluminum factory to purchase the metal they need. Transportation is also an important factor, as we can see: The capacity of electrolytic aluminum is distributed in north and west of China, but the main aluminum profiles manufacturers are concentrated in east of China. So obviously, the density of highway in China makes timely supply of raw aluminium.

Industrial chemicals, powders and die supply

Benefited from the convenience of the transport, other raw materials for surface treatment like extrusion profiles, anodic oxidation, powder coating can be arrived the aluminum factory very prompt.

On the basis of investigation, each aluminum factory is surrounded by 1 chemical supplier, 1 powder manufacturer and 3 mould factories. Which means our aluminum factory is timely supplied by these suppliers. On the other hand, MOQ for raw materials would be substantially reduced.

“It just like, when we have problem with our die in Vietnam, we have no choice but to send to China and purchase more same die from China, it needs more than 3 days to fix even 1 mold. but in China, you only ask the die supplier to bring it back and fix it, send it tomorrow, with nitriding of course.” Said by David, who is doing the sourcing business between China and Vietnam.

For Cheetah Aluminum, we rarely make lots of stocks of powders in our warehouse, the most important reason is powders have the expiration date, due to we got a great location (surrounded by raw materials’ manufacturers), only purchase the powders by proportion of the orders is the right choice. So we keep all the powders fresh as oven-fresh. Besides, we are located in Guangdong province, southeast of China, The weather can reach 40 ℃ in summer, powder deterioration is an occurrence.

As per the die design and delivery, we are going to talk about optimizing the cost of custom aluminum extrusions, in fact, the total price tag comes down to a combination of many factors, but the die is a direct element. H13 die steel is the most common material for extrusion aluminium profiles, as mentioned above, all factories are easier to purchase metals very timely, in this case the whole industrial chain gets integrated, manufacturer of aluminum profiles can minimize the cost and manage the delivery time shorten by 2-3 times.

Accessories products for one time purchasing

As you might expect, before the import come into effect, you could buy all you need in one space or country. When you decide to buy the window or door aluminium profiles, relevant accessories like handle, hinge, roller or lock are still needed, large assortment makes the import be more difficult. But this issue seems to be overscrupulous in China.

If you decide to buy the modular assembly aluminium profiles, like T-slot, you want ask the supplier to provide you also the screw and nut, or the other joints. More than geometry for sticking together, “Nut tracks” include a channel designed to accommodate a hex-head nut or bolt as needed, highly modular, for this reason it is better to import by the containers with T-slot and relevant accessories.

Second largest aluminum producer —— India

India is the second largest aluminum producer after China, Huge population advantage and growth attracted a lot of foreign investment at the industrial field. India’s bauxite are widely distributed about 590 million tons, with the vast majority of production procured by local aluminum companies and a small proportion exported abroad. Due to the inconveniences of transportation in India, the high cost of land transportation and the mediocre quality of ore, the competitiveness of India is declining.

Despite ample domestic aluminium capacity, India imports 50 % of its aluminium needs. India imports both primary and scrap aluminium, 591,000 tons and 1.288 million tons respectively in 2020. Especially for scrap aluminium, which India imports even more than raw aluminium due to factors such as economy and rapid development of domestic automobile industry.

Turkey and India are uniquely positioned to handle international trading, first of all, English speaking drastically shorten the communication progress. The demand of aluminum profiles is getting increasing during the world, turkey is also a powerhouse of industrial manufacturing, just need to figure out lower the cost in the period of production. As per Vietnam and China, the most important thing is to promote the English and services. Nowadays, the popularity rate of English among young Chinese has reached 94%.

Logistics costs & tariffs

Covid-19 has made us aware that how much it affects the costs of commodities and transportation. For both ocean and near-sea shipments, prices have risen sharply in the wake of the pandemic. Compare with before pandemic outbreak, freight cost for 45 HC container to Latin America is a tenfold increasing. For example, if you buy 1 piece of aluminum jamb, total amount will be 4 USD, but after pandemic, the cost may get to 4.5 USD per piece. It caused major fluctuation in the cost of container shipping, the rising cost of shipping cost ultimately impact the final price tag facing aluminium profiles consumers.

Additionally, customs clearance charge is always a decisive factor of import. Since China-United States trade war, many countries have imposed import tariffs on Chinese aluminum products, on the heels of the sanction, many countries such as Vietnam, Australia and EU started to issue the anti-dumping policy to against China, the highest duty even reaches to 101%, The barriers of international trade pushes aluminum factories like us have to find a foothold in worldwide.

Looking for a superior supplier of aluminum profiles in China?

Only the quality can ensure the stability of customer’s sales. Over last 10 years, we keep focusing and emphasis on the requirements of customers. Not only produce the exact quality as the sample approved, but offer some valuable information in aluminum sections.

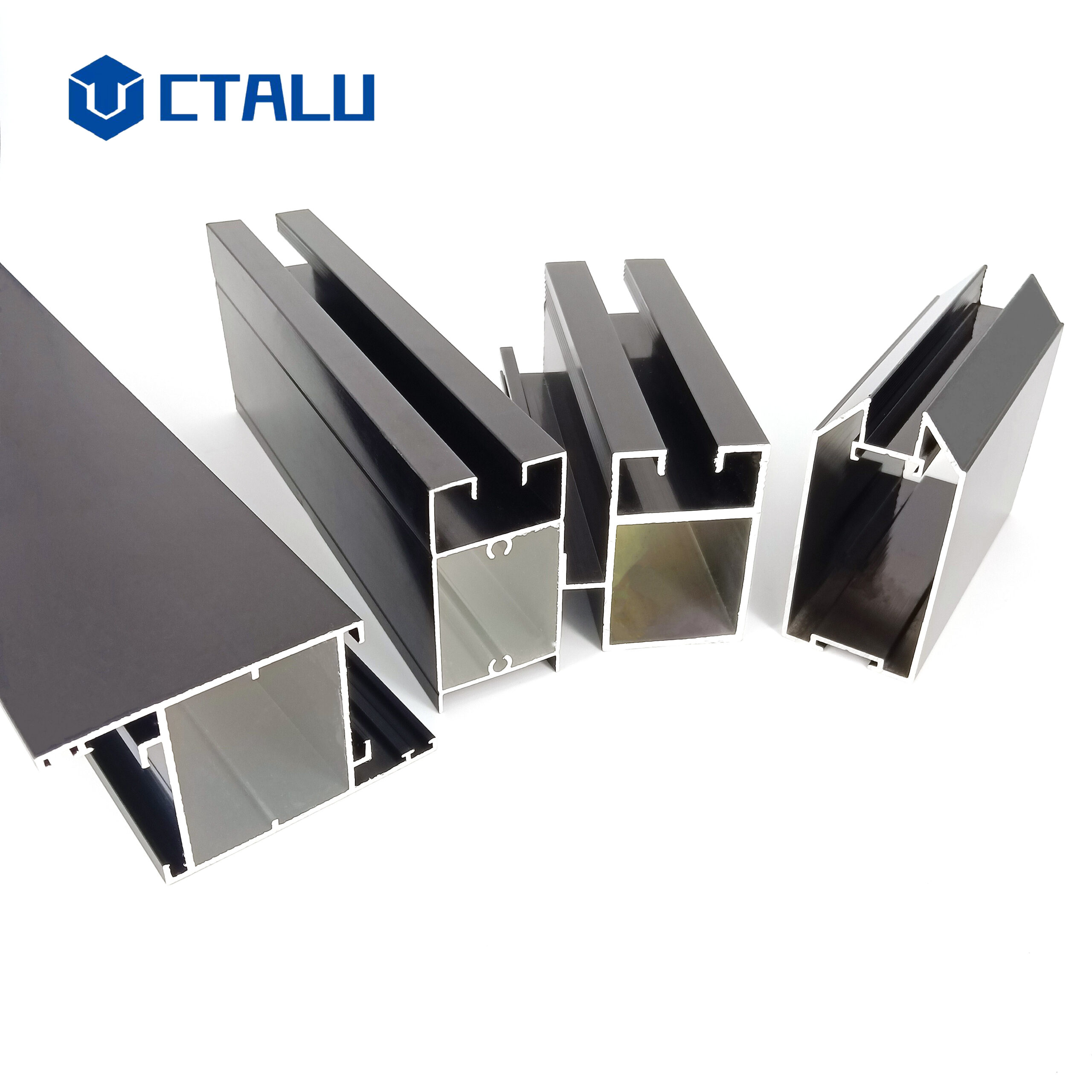

Cheetah Aluminum has a complete aluminum profile production line, from mill finish, to any kind of surface treatments, such as anodizing profiles or powder coated profiles, wood grain or electrophoresis.

We insist on the use of standard aluminum alloy production, firmly do not use low quality powder. For decades, the surface technology of aluminum profiles has been constantly updated. If you need additional insight, our aluminum experts and designer can help you decide the best design, surface finish and temper needed to achieve your goals at a cost competitive, best extrusions fit within your budget.

Any questions please contact or inquiry, please feel free to contact:

Email: simon@ctalu.com