Product description of Purification workshop profiles

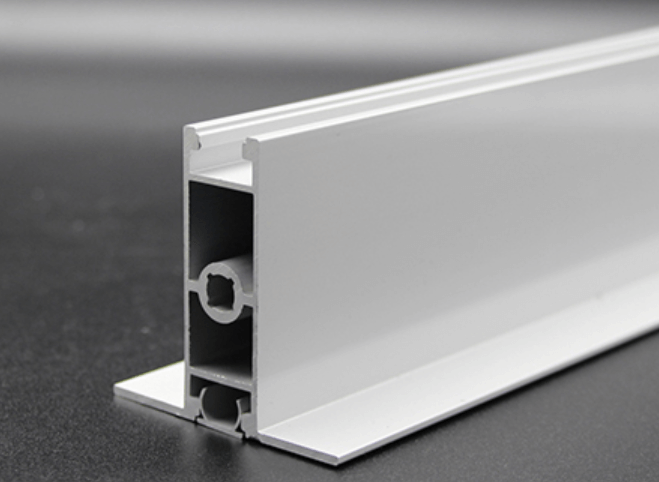

The purification workshop materials are the walls and roof plates of the purification workshop, which are generally made of 50mm thick sandwich color steel plates.

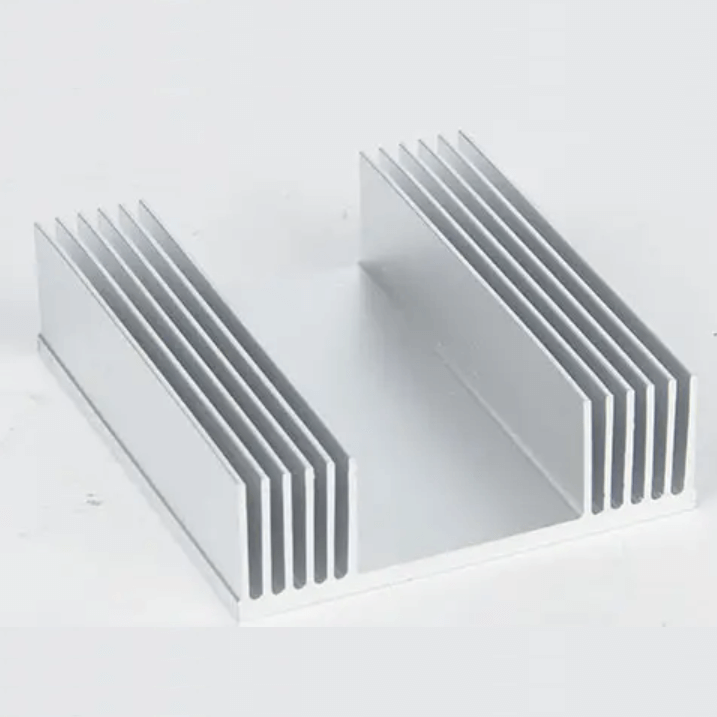

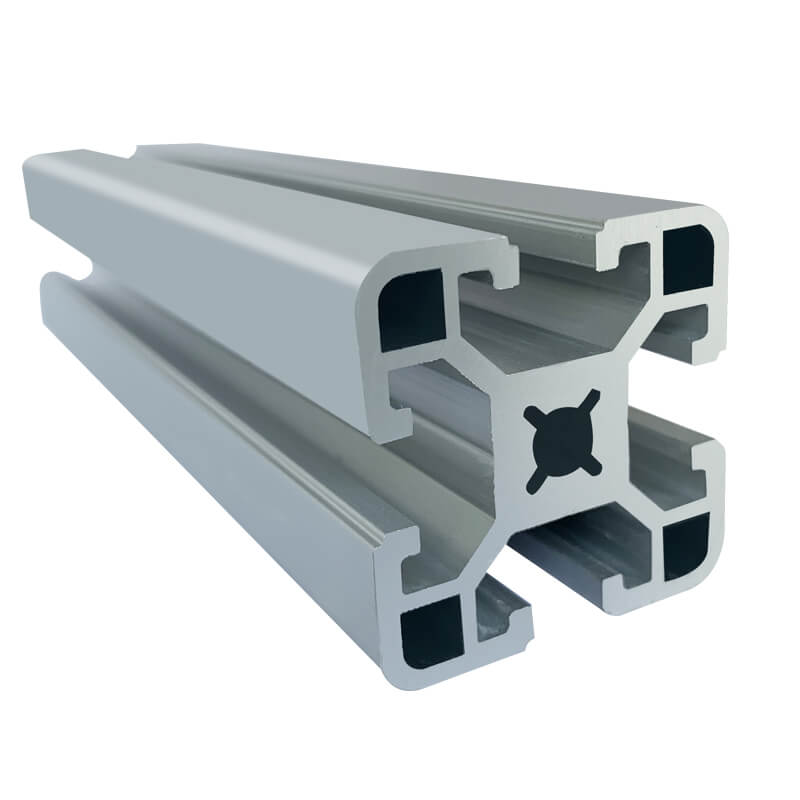

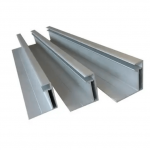

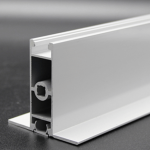

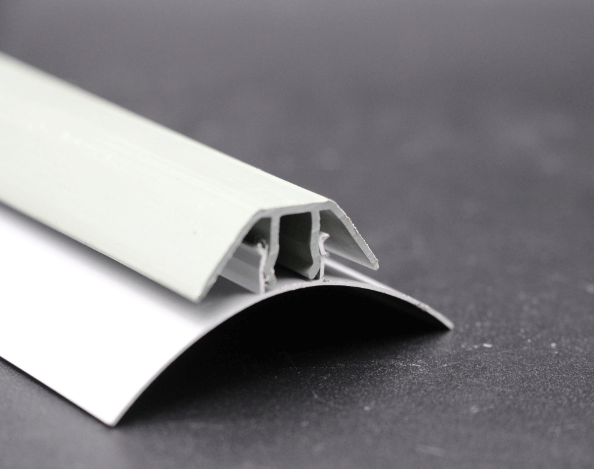

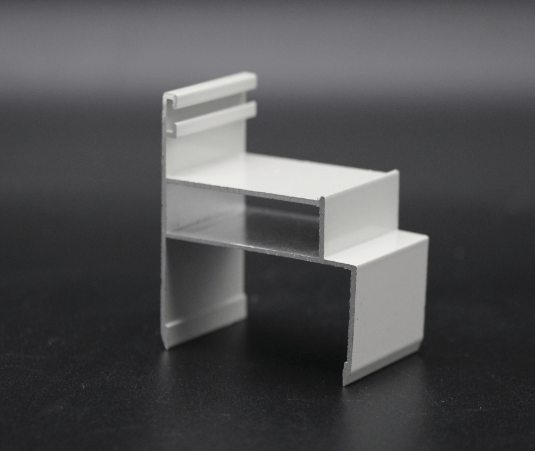

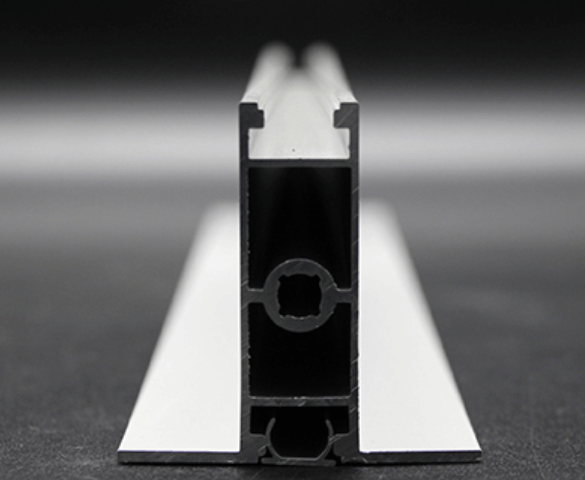

Arc wall corners, doors, window frames, etc. are generally made of special aluminium oxide profiles.

The ground can adopt an epoxy self-leveling floor or high-grade wear-resistant plastic floor.

If there are anti-static requirements, an anti-static type can be selected.

The biggest purpose of the purification workshop is to ensure that the cleanliness of the product production environment meets certain requirements, so there are requirements for the assembly materials.

The purified aluminium is extruded with 6063-t5 material,

and the surface is anodized to prevent the possibility of oxidation

Purification principle

Air flow → primary purification → humidification section → heating section → surface cooling section → medium efficiency purification → fan air supply → pipeline → high efficiency purification outlet → blowing into the room → taking away dust, bacteria and other particles → return air shutter → primary purification

Repeat the above process to achieve the purpose of purification.

Advantages of Purification workshop profiles

1. Simple and beautiful

2. Strong rigidity

3. Good thermal insulation performance

4. Good moisturizing performance

5. Good cleaning performance

6. Easy construction

7. Electrostatic prevention.

8. Environment protection

The purified aluminium is mainly treated by electrostatic and spraying process, with smooth surface, flat and beautiful appearance, and many decorative effects!

The aluminium of Cheetah aluminium International Co.,Ltd has strong plasticity, good productivity, good thermal conductivity and conductivity, and meets the production standard of the workshop,is you best choice.

We can also provide processing of other aluminium materials.

Welcome to consult at home and abroad for more product content.