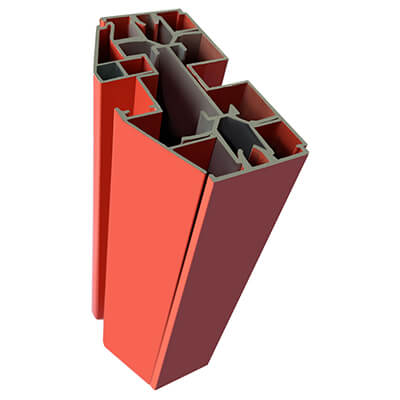

Powder coated

Powder coating refers to: using powder spraying equipment (electrostatic spraying machine) to spray powder coating onto the surface of aluminum profiles. Under the action of electrostatic, the powder will be evenly adsorbed on the surface of the aluminum profile, forming a powder coating; the powder coating is baked at high temperature to form the final coating.

The coating effect of powder coating is better than the spray painting process in terms of mechanical strength, adhesion, corrosion resistance and aging resistance, and the cost is lower than the spray painting technology.

CTALU produces powder coated aluminum profiles with absolutely no toxic raw materials, using exclusively environmentally friendly, well-known powder coatings. In order to achieve better performance of powder coated aluminum profiles, CTALU strictly cleans the surface of aluminum profiles before coating to improve the efficiency of coating. We keep our workshop clean and tidy and clean it thoroughly every time we spray a different color of powder.

Cheetah has many years of experience in manufacturing powder coated aluminum profiles and is able to meet over 90% of oversea customers' needs. Customers can place orders according to Lauer color cards (or other international color cards). After sample testing, meet customer requirements.

| Poder Coated Standard | |||||||

| Performance of the coating | Glossiness | Coating Layer Thickness | Color | Degree of Stress Resistance | Shock Resistance | Exterior Appearance | |

| Maximum Partial Film Thickness | Minimum Partial Film Thickness | ||||||

| 60 | ≤120 | ≤40 | Basically the same as the color plate | ≥80 | The surface of the aluminum profile is indented to a depth of 6mm, and the coating surface will not be cracked. | The surface of the sprayed aluminum profile is required to be smooth and no wrinkles and bulges are allowed. The surface quality is negotiated by the two cooperating parties | |